Case Sealers We Offer

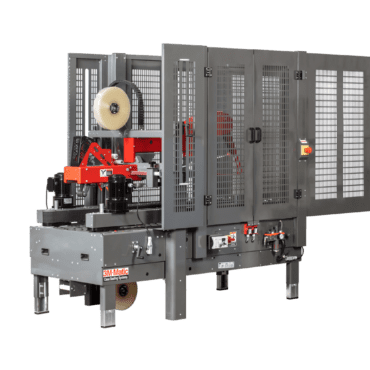

Korpack understands that getting your packages out the door securely sealed and in the fastest, most efficient manner is of paramount importance to every company. It all starts with 3M-Matic case sealers. For over 50 years, packaging facilities have relied on these highly productive case sealers for consistent, efficient case sealing, day after day. Korpack customers can attest to their dependability and reliability.

$23,282.83

MSRP:

$23,282.83

MSRP:

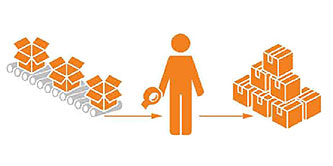

Hand taping 200+ same-size boxes each day is highly inefficient. 3M-Matic Case Sealers can cut labor expenses, increase productivity, and give you more consistent sealing.

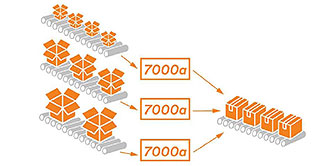

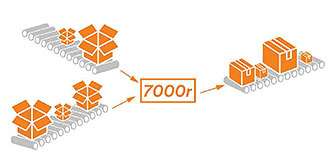

Placing one adjustable case sealer on each line can seal long runs of identical boxes.

One random case sealer that automatically adjusts for each box can easily tape different size boxes from your packaging lines.

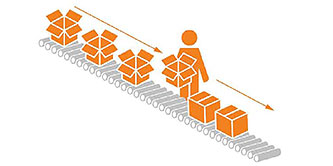

If you’ve dedicated part of your staff to folding flaps and feeding boxes into a case sealer, consider automating the end of the production line with the 3M-Matic Automatic Adjustable Case Sealer to help reduce your overall costs.

A variety of markets rely on high-quality case sealing. They include: food and beverage, medical devices, pharmaceuticals, electronics, retail, manufacturing, and distribution centers, to name just a few.

These rugged units can be set up quickly through manual adjustments to accurately and reliably seal runs of the same size cartons. After the run is complete, manual adjustments of the machine can be made for a new run.

Adjusting automatically, these rugged case sealers perfectly and dependably seal cartons of various sizes from the same production line or different production lines set up to feed one sealing line.

The 3M-Matic Case Former and Sealer automatically forms boxes, eliminating the awkward bottom flap-folding step in manual case packing. It can help boost assembly line speed and increase productivity, depending on processes, by up to 25%.

This feature allows for flaps to be automatically folded, eliminating the need for an operator to be constantly present. The sealers quickly and easily adjust cases to a wide range of heights and widths.

Korpack packaging experts are readily available to assist you with finding the best solution. Just click the chat button below or Contact Us for more information.

Using the wrong case sealer can be very costly. Are you experiencing any of these costly end-of-line issues?

Material Waste: The costly disposing of tape before the roll is depleted

Equipment Downtime: Experiencing shutdowns due to frequent changeovers or unplanned maintenance or repairs

Injuries and Ergonomics: The repetitive motion and the sharp knife edge on a hand dispenser causing safety issues

Missed Application: Experiencing missing or popped tape, or tape applied in the wrong spot

Manual Rework: Too many operators on the line or re-taping boxes the sealer missed

Equipment Upkeep Costs: Performing unplanned repairs or maintenance, or exceeding your parts budget

An adjustable sealer seals a long run of cartons that are the same height and width by means of manual adjustments. A random case sealer will adjust itself to the height and width of individual boxes as they arrive.

Many times, top and bottom belt case sealers are the best drive system configuration and are highly recommended for most carton-sealing applications. A four-belt system will securely drive the carton through the case sealer without skewing it or tipping it and tape is securely applied down the center seam. For example, your operation will keep running smoothly when a tall but not very long box is held by the top and bottom belts so the carton doesn’t tip as it’s taped.

Though side belt case sealers can be used for all size boxes, they’re especially useful for taping narrow-width boxes. You’ll want to make certain that the sided belts are spring-loaded, which will allow a little give when there is a slight variance in box width, such as with overstuffed cartons.

There are only two drive belts at the bottom of a bottom belt drive case sealer. This requires a little more weight in the box in order to have stable conveyance through the case sealer. Big benefits of bottom belt machines having only two belts are lower cost and they can be a great place to start improving productivity.

Occasionally you’ll have box sizes which are outside of the typical operating range of a case sealer because they’re too short or too large. 3M case sealers are able to be customized to satisfy your unique box requirements. Sometimes this may simply be an extension of the existing columns. In other situations, a custom sealer can be engineered by Korpack from the ground up using standard components.

This is going to depend on how you’re currently packaging your product, but in 90% of cases it will reduce your costs. Case sealers can replace hand taping and tape your boxes for shipment. By shifting to a flap-folding machine you’ll reduce costs by removing the need for an operator needed to fold the top flaps and present the box to the case sealer. You can further reduce costs and increase productivity through the use of a case sealer to pre-form cartons. A Korpack equipment specialist can best recommend a solution after visiting your site and discussing your needs.

Though there are a lot of variables that go into recommending a specific tape, we always recommend Scotch Box Sealing Tape for all 3M-Matic case sealers. They’re engineered to work together as a system, providing you with the best equipment, the best taping head, and the best carton-sealing tape. You consistently get great adhesion, as well as reliable and consistent case sealer performance.

3M-Matic case sealers have a great reputation because they’re rugged and durable. They’ve been in use for over 45 years, and there are many customers using equipment that’s over 20 years old, which is a testimony to their durability. Operating conditions and maintenance do affect longevity, and every customer’s factory is different. Korpack has a number of preventive maintenance plans available and 24/7 emergency service if you need it. Any 3M-Matic machine is a good long-term investment.

Each of the machines operating manual details available parts and recommended maintenance procedures. Most case sealers are fairly basic machines having few wear parts needing periodic replacement. This will depend on usage, and drive belts and taping head blades uses to cut the tape occasionally need replacement. Korpack recommends participating in the 3M Systems Agreement Program by purchasing Scotch Box Sealing Tape from us, which makes these parts available to you at no cost! Otherwise, Korpack has numerous 3M-Matic parts in stock and a full-service department for professional installation.

Korpack has got you covered! 3M-Matic case sealers have parts that may wear over time and need replacing, including blades, belts, springs, and rollers. We always recommend 3M replacement parts which are engineered for rugged duty with steel construction and epoxy-coated surfaces.

For replacement parts please contact us or call our service department directly at 844-SERVKOR (737-8567)

KORPACK offers a selection of case sealers that are integral to streamlining your packaging line. Our case sealers are designed for businesses that demand reliability and efficiency in their sealing operations.

Optimize Your Packaging Process